1. Wire drawing machine:

Application:

This equipment is used to remove the steel wire of the rim on both sides of the tire. The diameter of the tire is 500-4200 mm. After removal, the next step of tire treatment is more convenient and faster, and the economy of waste tire treatment is improved.

|

Features: 1. Designed with high-strength positive pull hook; 2. The unique design of aircraft block s lot, can effectively remove the steel wire on the 2 sides of the tire. 3. Integrated control, easy to learn, remote control operation. 4. Every moving part is operated by hydraulic cylinder, with operation anglarge fension, The efficiency is rather high. 5. The main frame can be lifted, so that the application range of the detachable tire is enlarged |

|

2.Shears

Application:

This equipment is mainly used to cut and pull the tire after removing thering steel wire, and the tire bottom can be cut in all directions.Which is easy for subsequent treatment at the recycling plant.

|

Features: 1.0ne-person one-stop cutting operation is adopted. 2. Integrated control, easy to use, intuitive and convenient operation. 3. PLC control is adopted, with high reliability and easy maintenance. 4. The tire roller conveyor is driven by the motor directly connectedto the reducer, with stable operation and high transmission efficiency. 5. The front and rear double- row rollers are adopted for conveying. The conveying speed is adjustable. |

|

|

3. Shredder Function 1. RSC series dual-shaft shredder is strong and durable. 2. The dual-shaft blade roll structure has the advantages 3. The blade of the shredder is forged with material H13, 4. This machine is equipped with dual protection of mechanical and electrical overload. 5. Adopting a double-material area operation mode, wherein the thick blade area on one side is used for processing large materials, the thin blade area is used for processing small block materials; 6. The left and right double material press arms are adopt and can be independently controlled; 7. The split type upper and low material boxes are adopt with movable connection, so that the installation and the maintenance are convenient and quick. 8. Use a high hardness and large fixed blade to remove the stuck material in the spacer sleeve. 9. Planetary reducer is adopted for the reducer: high bearing capacity, stable operation, low noise, Large output torque, large speed ratio, high efficiency and safe performance. |

|

4. Steel wire separator

1. The tire steel wire separator is mainly used to shear the rubber block through the file on the rotating knife roller and the file on the box body.Crushing action, the rubber block is torn up and cut into smaller particles.In the process of crushing the rubber block, the steel wire and part of the fiber are separated from the rubber.

2. The bottom of the tire steel wire separator is equipped with a screen. Materials smaller than the screen holes will fall out through the screen. Materials larger than the screen holes will fall out through the screen.It will be left in the crushing cavity and crushed again until it falls out of the screen until it is smaller than the screen hole.

|

5. Belt magnetic separator The material is evenly fed to the magnetic field area on the upper part of the rotating drum through an electromagnetic vibrating feeder. The magnetic material is adsorbed on the surface of the drum and rotates with the drum. |

|

6. Multi-stage vibrating screen

1. Using the principle of vibration motor excitation, the material is thrown up on the screen surface and moves forward in s straight line to achieve the purpose of screening with a reasonably matched screen. The machine consists of a base, a vibration chamber, a vibration motor, a vibration absorber, etc. The machine vibrates smoothly with low noise, simple operation and excellent screening performance .

2. The basic principle is to use the weights (unbalanced weights) installed at the upper and lower ends of the motor shaft to. The rotational motion of the machine is converted into horizontal, vertical and tilted three-dimensional motion, and then this. The movement is transmitted to the screen surface. If the phase angle of the upper and lower hammers is changed, the behavior of the raw materials can be changed.

7. Fiber separation tower

The fiber separator is a fiber processing device that uses the difference in specific gravity between rubber and fiber to remove light and heavy impurities in the rubber raw material.The role of relief and screening .

8. The overview of finished products

|

|

| Ring Steel Wire | Tread wire |

|

|

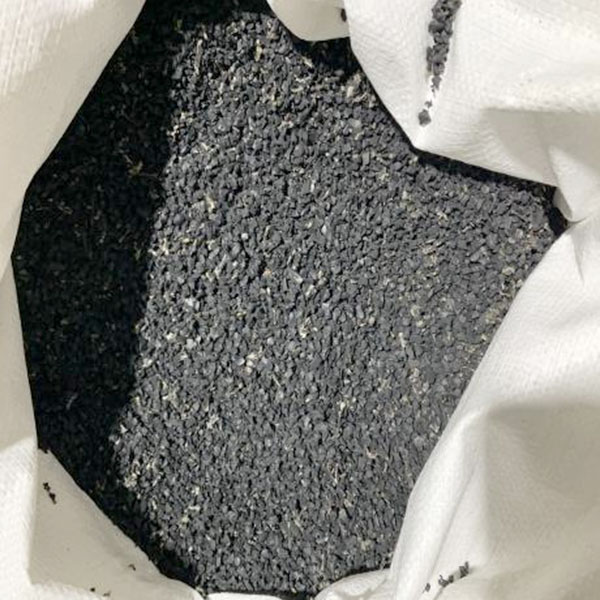

| Fiber | 5mm rubber powder particles |

|

|

| 3mm rubber powder particles | 1mm rubber powder particles |

9. The customer site in Novosibir sk, Russia